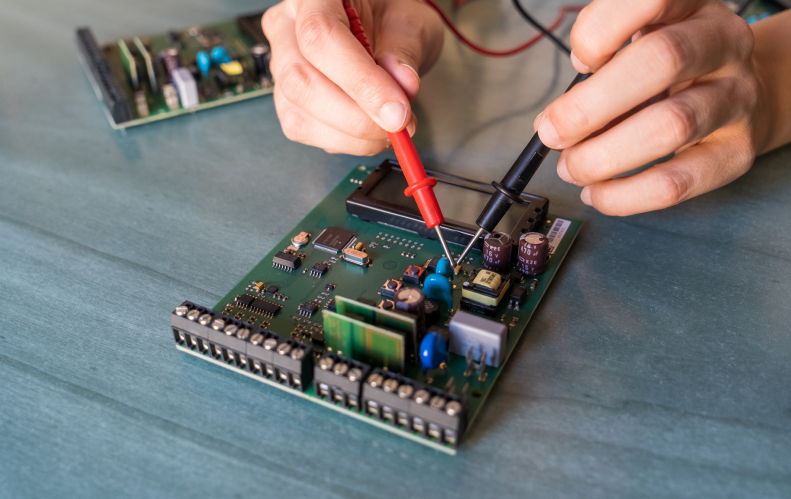

The Role of Probes in Electronic Testing and Manufacturing

In the world of electronics manufacturing, ensuring accurate testing is essential for producing reliable products. Various types of probes, such as the board test probe, spring contact probe, and coaxial probe, play a critical role in achieving this precision. Additionally, dependable components like the battery connector and receptacle help maintain seamless connections. Selecting the right probes and connectors can significantly enhance the efficiency and accuracy of circuit diagnostics and testing processes.

In this guide, we’ll explore the different probes and connectors and their importance in electronic testing and manufacturing.

The Versatility of a Board Test Probe for Circuit Diagnostics

A board test probe is one of the most versatile tools in circuit diagnostics. These probes are designed to make electrical contact with specific points on a printed circuit board (PCB) to test for continuity, functionality, and potential faults.

Key Benefits of Board Test Probes:

- High Precision: Enables accurate testing of intricate circuits.

- Durability: Designed for repeated use in automated test equipment (ATE).

- Flexibility: Suitable for both in-circuit testing (ICT) and functional testing.

Using a high-quality board test probe ensures that even the smallest faults can be detected and corrected early in the manufacturing process, improving overall product reliability.

How Spring Contact Probes Enhance Precision

Spring contact probes are designed to provide reliable contact with test points under controlled pressure. These probes are commonly used in PCB testing and semiconductor testing.

Advantages of Spring Contact Probes:

- Consistent Contact Pressure: Ensures accurate readings by maintaining a stable connection.

- Long Lifespan: Designed to withstand thousands of test cycles.

- Versatility: Available in various sizes and configurations to meet different testing needs.

Spring contact probes are essential for achieving consistent and accurate test results, especially in high-volume manufacturing environments where precision is critical. Pairing them with a reliable board test probe can further enhance testing accuracy.

Using a Coaxial Probe for High-Frequency Testing

When testing high-frequency signals, a coaxial probe is the go-to solution. Coaxial probes are designed to minimize signal loss and interference, making them ideal for applications such as RF testing and high-speed digital signal analysis.

Benefits of Coaxial Probes:

- Low Signal Loss: Maintains signal integrity at high frequencies.

- Shielded Design: Reduces electromagnetic interference (EMI).

- Precision Measurements: Provides accurate readings for sensitive circuits.

Incorporating coaxial probes into your testing process ensures that high-frequency circuits are evaluated accurately. These probes are often used alongside board test probes and spring contact probes to cover a wide range of testing requirements.

The Importance of a Reliable Battery Connector

A battery connector ensures secure and consistent power delivery during the testing process. Inaccurate or unreliable power connections can lead to faulty test results, impacting the quality of the final product.

Why Battery Connectors Matter:

- Reliable Power Supply: Ensures accurate test conditions.

- Durability: Designed to handle repeated connections and disconnections.

- Versatility: Suitable for various battery types and applications.

Using a high-quality battery connector eliminates potential power issues, ensuring that all tests reflect the true performance of the device under test.

Ensuring Seamless Connections with Quality Receptacles

A reliable receptacle is the final piece in achieving seamless and accurate electronic testing. Receptacles provide secure housing for probes and connectors, maintaining stable contact during the testing process.

By combining board test probes, spring contact probes, coaxial probes, battery connectors, and dependable receptacles, manufacturers can ensure accurate diagnostics, reduce errors, and enhance product reliability. Investing in quality testing components is essential for achieving the highest standards in electronic manufacturing.

For more information on high-quality probes and connectors tailored to your needs, visit Petracarbon or Contact Us for expert advice.