Hydraulic pumps are the heart of hydraulic systems, converting mechanical energy into fluid power to drive machinery in industries like construction, oil and gas, and manufacturing. At Petra Carbon, we design high-efficiency hydraulic pumps that prioritize reliability, precision, and longevity, ensuring your operations run smoothly under the most demanding conditions. This guide explores hydraulic pump types, applications, and why Petra Carbon is the trusted partner for industrial hydraulic solutions.

What Is a Hydraulic Pump?

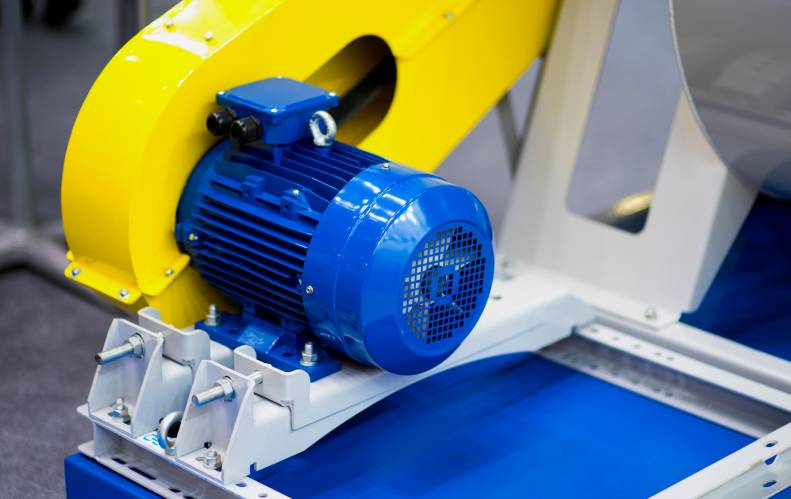

A hydraulic pump generates flow to transmit power within a hydraulic system, pressurizing fluid to operate cylinders, motors, and other components. Unlike electric pumps, hydraulic pumps excel in high-torque, heavy-load environments.

Key Features of Petra Carbon’s Hydraulic Pumps:

Pressure Range: 500 to 10,000+ PSI for diverse industrial needs.

Durability: Cast iron or stainless steel construction for corrosion resistance.

Compatibility: Works with hydraulic torque wrenches and flange alignment tools.

Explore our hydraulic tools catalog for complete system solutions.

Types of Hydraulic Pumps

Gear Pumps

Use Case: Cost-effective power for machinery like conveyor belts.

Features:

– Fixed displacement, 1,000–3,000 PSI.

– Compact design for tight spaces.

Piston Pumps

Use Case: High-pressure applications (e.g., hydraulic presses, cranes).

Features:

– Variable displacement, up to 10,000 PSI.

– Energy-efficient for continuous operation.

Vane Pumps

Use Case: Mid-pressure systems requiring low noise (e.g., manufacturing lines).

Pair With: Test fixtures for precision fluid control.

Applications of Hydraulic Pumps

Construction Machinery

Power excavators, bulldozers, and cranes for heavy lifting and digging.

Oil & Gas

Operate blowout preventers (BOPs) and drilling rigs in extreme environments.

Aerospace

Fuel hydraulic actuators in aircraft landing gear and flight control systems.

Manufacturing

Drive presses, injection molding machines, and automated assembly lines.

Benefits of Hydraulic Pumps

| Advantage | Impact |

| High Power Density | Compact size with immense force output. |

| Precision Control | Adjustable flow/pressure for exact operations. |

| Durability | 10,000+ hours of service life in harsh conditions. |

How to Choose the Right Hydraulic Pump

Step 1: Determine Flow & Pressure Needs

Calculate required GPM (gallons per minute) and PSI for your system.

Step 2: Select Pump Type

Gear pumps for simplicity; piston pumps for high-pressure demands.

Step 3: Evaluate Power Source

Electric, diesel, or PTO-driven options.

For custom configurations, contact our engineers.

Why Petra Carbon’s Hydraulic Pumps Excel

Rigorous Testing: Validated under ISO 4406 cleanliness standards for fluid compatibility.

Global Support: 24/7 technical assistance and spare parts availability.

Custom Solutions: Tailored pumps for unique flow, pressure, or mounting needs.

FAQs About Hydraulic Pumps

How often should hydraulic pumps be serviced?

Every 1,000–2,000 hours or as per OEM guidelines.

Can hydraulic pumps handle synthetic fluids?

Yes! Specify fluid type during purchase for material compatibility.

What’s the lead time for custom pumps?

Typically 4–6 weeks, depending on complexity.

At PetraCarbon, we engineer pumps that deliver unmatched performance, whether you’re powering construction sites or precision manufacturing lines.

🔗 Contact Us for expert guidance or explore our Hydraulic Tools Catalog.

Powering performance!