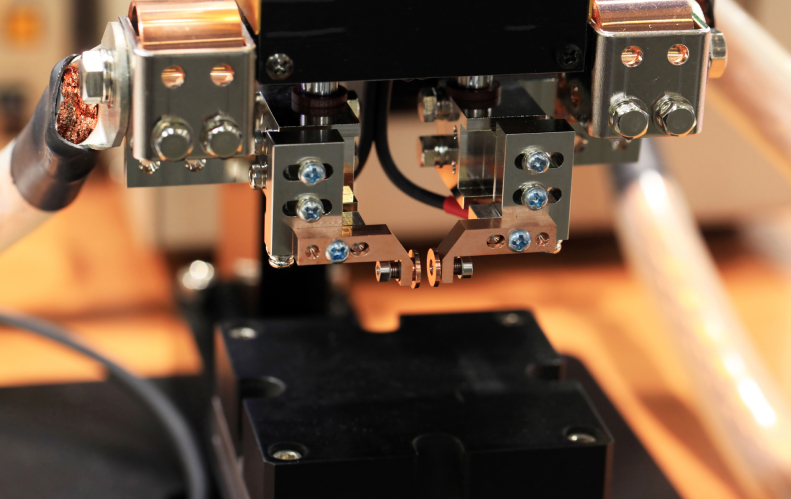

In today’s high-speed electronics manufacturing environment, accuracy and signal integrity are more important than ever-especially in high-density test fixtures. At the heart of these test systems lie spring contact pins, which play a critical role in achieving reliable contact, signal consistency, and mechanical durability.

From ICT systems like Keysight 3070 to Teradyne platforms, the performance of each test cycle depends on the quality of the test socket and probe architecture. Petracarbon, headquartered in Singapore, offers precision-engineered spring contact pins tailored for demanding test applications.

Engineering Requirements for High-Density Test Fixtures

Why Contact Precision Defines Fixture Performance

In high-density environments, even the slightest deviation in contact force or misalignment can lead to inconsistent test results. As PCB designs become more compact, fixture designers must account for pitch, compression, resistance, and signal path geometry. Poor probe quality can result in damaged pads, false failures, or degraded signal measurements.

Challenges in High-Density PCB Testing

Testing advanced boards-especially those using 3070 or Teradyne systems-presents several challenges:

- Tight pitch requirements with hundreds to thousands of pins

- High insertion cycles exceeding 100,000 actuations

- The need for stable, low-resistance connections over time

Petracarbon solves these challenges with expertly selected spring contact pins, ensuring the performance and longevity of your fixture.

Compatibility with 3070 & Teradyne ICT Systems

Fixture Integration in 3070 and Teradyne Platforms

Platforms like Keysight 3070 and Teradyne Test Station are the gold standards in In-Circuit Test (ICT). However, they demand high-tolerance fixtures. Petracarbon’s spring contact pins are designed specifically for these systems, ensuring seamless alignment, connectivity, and low-resistance contacts.

Contact Density vs. Signal Integrity

As devices scale down and test coverage increases, engineers must balance pin density with signal clarity. Optimized contact geometry in spring contact pins minimizes crosstalk and ensures accurate analog and digital measurements.

Key Features of Petracarbon’s Spring Contact Pins

Material Engineering and Plating Options

| Feature | Description |

| Plating | Gold over nickel for conductivity and corrosion resistance |

| Barrel | Stainless steel or brass for mechanical durability |

| Plunger | Beryllium copper for elasticity and fatigue resistance |

These materials ensure that spring pins withstand long test cycles without degrading electrical or mechanical performance.

Specialized Tip Styles for Advanced Boards

Different PCB designs require specific pin tips:

- Crown Tip – Best for through-hole or pad connections

- Dome Tip – Ideal for flat pads or component leads

- Serrated Tip – Penetrates oxide layers for clean contact

Matching the tip to the DUT surface improves first-pass yield and avoids costly retests.

Test Socket and Fixture Design Considerations

Optimizing Layout for Accessibility and Maintenance

A good fixture design should allow easy access for replacing damaged or worn pins. Petracarbon’s fixture systems are designed with modularity in mind, making it easy to remove and replace spring contact pins during maintenance.

Fixture Stiffness and Contact Force Uniformity

Uniform contact force is critical to prevent deflection in the fixture base. Petracarbon integrates mechanical supports and precision alignment features into its 3070-compatible fixtures, ensuring repeatable performance across all probes.

Common Testing Issues Solved by Premium Spring Contact Pins

- Intermittent Contact

Use gold-plated, tight-tolerance spring pins to maintain signal continuity throughout thousands of cycles. - High Contact Resistance

Select low-force pins with precision-ground plungers-ideal for sensitive analog and RF testing. - Test Pad Damage

Choose crown or floating tips that self-center, reducing mechanical wear and PCB gouging.

Industry Applications & Case Studies

Semiconductor & Consumer Electronics

In high-speed SoC or memory device testing, spring contact pins ensure signal accuracy and long pin life, even with micro-pitch layouts. Petracarbon supplies fixtures for high-volume semiconductor clients across Asia and Europe.

Automotive and Industrial Electronics

From battery management systems to ECU testing, automotive test platforms demand reliability under vibration and stress. Spring pins from Petracarbon maintain performance through environmental cycles and repeated testing.

Why Petracarbon Is Trusted for High-Density Test Solutions

For over 40 years, Petracarbon has supplied world-class fixture systems and test sockets to leading OEMs and EMS providers. Our in-house engineering and ISO-certified quality ensure that every product-especially our spring contact pins-meets your most demanding test specifications.

Need tailored advice? Contact Petracarbon here

Engineering Accuracy Starts with the Right Spring Contact Pins

Spring contact pins are more than just test probes-they’re critical links in ensuring accurate, repeatable, and fast electrical testing. Whether you’re running a 3070, Teradyne, or custom fixture, using the right pins means better yields, fewer retests, and longer-lasting test sockets.

With Petracarbon’s expertise, materials science, and custom fixture design, you’re not just buying a part-you’re ensuring test excellence from the ground up.