In industrial environments, precision, efficiency, and reliability are essential for smooth operations. Whether in electronics manufacturing, oil and gas, or telecommunications, businesses rely on advanced testing solutions and hydraulic tools to maintain, diagnose, and optimize their equipment.

Among these solutions, In-Circuit Testing (ICT) plays a crucial role in ensuring the quality and performance of printed circuit boards (PCBs) used in modern electronics. At the same time, hydraulic tools like torque wrenches, bolt tensioners, and flange alignment tools are essential for heavy-duty industrial maintenance.

With over 40 years of expertise, Petracarbon is a leading provider of ICT and hydraulic solutions, helping industries improve testing efficiency, reduce downtime, and ensure operational reliability.

In-Circuit Testing: The Backbone of Electronic Diagnostics

What is In-Circuit Testing (ICT)?

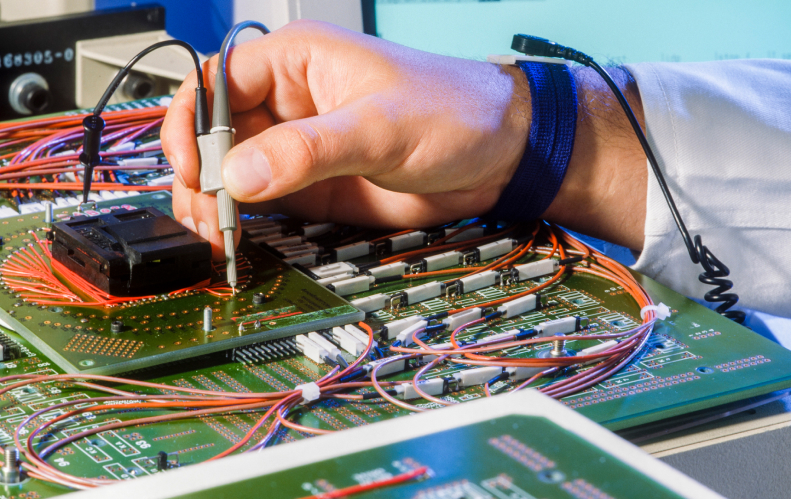

In-Circuit Testing (ICT) is a highly effective method for testing and diagnosing printed circuit boards (PCBs). Unlike functional testing, which verifies the overall performance of a board, ICT examines each individual component, ensuring that:

- Resistors, capacitors, and transistors are properly soldered and functional

- No short circuits, open circuits, or incorrect component placements exist

- ICs (integrated circuits) are correctly installed and operate as expected

ICT allows electronics manufacturers to detect and fix defects early, reducing rework costs and improving product reliability.

Why is ICT Crucial in Electronics Manufacturing?

Electronics manufacturers, especially those in the semiconductor and telecommunications industries, rely on ICT for high-speed, high-accuracy diagnostics. The benefits of ICT include:

- Faster Testing Process: ICT systems like Teradyne 3070 and Keysight ICT solutions perform thousands of tests within seconds.

- Early Defect Detection: ICT identifies manufacturing defects before final assembly, saving time and reducing waste.

- Higher Product Reliability: Ensures that every PCB meets industry standards, minimizing field failures.

- Lower Production Costs: Detecting errors early prevents costly product recalls and rework.

With industries demanding higher precision and efficiency, ICT is a fundamental requirement for quality control.

Key Components of an In-Circuit Test (ICT) System

An ICT system consists of several high-precision components that work together to provide accurate and efficient testing. Below, we break down the essential parts of an ICT system and their roles.

| Component | Function | Why Is It Important? |

| Fixture | Holds the PCB securely in place during testing | Prevents movement for accurate probe placement |

| Board Test Probe | Contacts test points on the PCB to conduct diagnostics | Ensures reliable signal transmission |

| Coaxial Probe | Measures high-frequency signals with minimal interference | Reduces signal loss and enhances accuracy |

| Battery Connector | Provides power to battery-operated PCBs during testing | Ensures stable voltage supply for accurate results |

| Receptacle | Acts as an interface for interchangeable probes | Allows quick probe replacements for different PCB designs |

| Test Socket | Secures ICs (integrated circuits) for testing | Prevents disconnection during diagnostics |

These components ensure seamless, high-speed, and precise testing in electronics manufacturing.

Leading ICT Solutions: Teradyne 3070 & Keysight ICT Systems

Teradyne 3070: A Leader in ICT Testing

The Teradyne 3070 ICT system is one of the most advanced and widely used in-circuit test platforms. It offers:

- High-Speed Parallel Testing: Reduces test time while increasing throughput.

- Advanced Diagnostics: Pinpoints faulty components with unmatched accuracy.

- Scalability: Supports a wide range of PCB designs for diverse applications.

Many telecommunications and semiconductor companies use Teradyne 3070 for its efficiency and reliability.

Keysight ICT Systems: Precision and Innovation

Keysight Technologies is another major player in ICT, providing high-precision electronic testing solutions. Their ICT systems are known for:

- Advanced Fault Detection: Minimizes false positives, improving test accuracy.

- Intelligent Automation: Reduces manual intervention, increasing productivity.

- Integration with Modern Industry 4.0 Platforms: Enhances connectivity and automation.

Both Teradyne 3070 and Keysight ICT systems are industry standards, ensuring high-quality PCB testing.

Case Studies: Real-World Applications of ICT Systems

Case Study 1: Enhancing PCB Testing with Teradyne 3070

A global electronics manufacturer faced challenges with PCB defect detection, leading to high product failure rates. By integrating Teradyne 3070 ICT, they achieved:

- 30% reduction in manufacturing costs

- 25% improvement in product quality

- Faster production cycles due to automated testing

By detecting soldering errors and component misplacements early, the company optimized efficiency and reduced waste.

Case Study 2: Improving Testing Accuracy with Keysight ICT Solutions

A leading semiconductor company struggled with inconsistent testing results, causing production delays. After implementing Keysight ICT systems, they saw:

- 40% increase in test accuracy

- 25% reduction in rework and repair times

- Higher customer satisfaction due to improved product reliability

These real-world examples highlight how ICT enhances testing efficiency and reduces production costs.

Best Practices for Using ICT Systems

To get the best performance from an ICT system, follow these expert recommendations:

Use High-Quality Fixtures and Probe: Precision-engineered fixtures, board test probes, and coaxial probes enhance testing accuracy

- Calibrate ICT Equipment Regularly: Regular calibration ensures consistent test results and minimizes false positives.

- Train Operators on Advanced ICT Systems: Proper training maximizes testing speed and reliability.

- Optimize Software for Automated Testing: Modern ICT systems, like Teradyne 3070 and Keysight, integrate smart automation for efficiency.

Following these best practices ensures flawless ICT implementation for manufacturers.

Conclusion: Optimizing Industrial Maintenance with ICT & Hydraulic Tools

In-Circuit Testing (ICT) is a critical technology for electronics manufacturing and maintenance, ensuring high-quality PCBs with minimal defects. With solutions from Teradyne, Keysight, and advanced ICT components like fixtures, board test probes, coaxial probes, battery connectors, receptacles, and test sockets, businesses can enhance product reliability and reduce costs.

For expert guidance on ICT systems and industrial maintenance solutions, visit Petracarbon or Contact Petracarbon for customized solutions.

Optimize your industrial maintenance today!