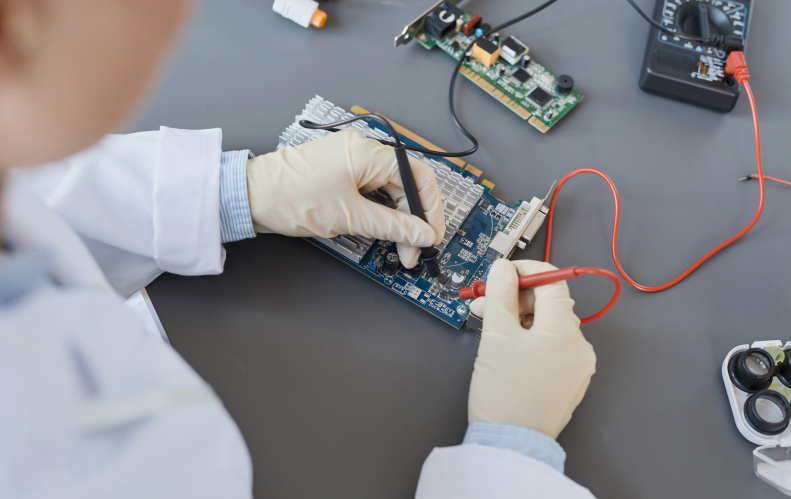

In-Circuit Test (ICT) is a cornerstone of electronics manufacturing, enabling rapid, precise validation of printed circuit boards (PCBs) for defects like shorts, opens, and component failures. At Petra Carbon, we deliver advanced ICT solutions that integrate seamlessly with industry-leading systems like Teradyne and Keysight, ensuring your production lines achieve near-zero defect rates. This guide explores how ICT works, its applications across industries, and why Petra Carbon’s expertise guarantees reliability in high-stakes manufacturing environments.

What Is an In-Circuit Test (ICT)?

In-Circuit Testing is a automated method used to validate PCB assemblies by measuring electrical properties (resistance, capacitance, etc.) at specific test points. Using fixtures like bed-of-nails testers or flying probes, ICT identifies manufacturing defects early, reducing rework costs and ensuring compliance with quality standards.

Key Features of Petra Carbon’s ICT Solutions:

High-Speed Testing: Validate thousands of test points in seconds.

Defect Detection: Identify opens, shorts, missing components, and incorrect values.

Integration: Compatible with Teradyne and Keysight testers for seamless workflows.

Explore our testing equipment catalog for ICT-ready systems.

Types of In-Circuit Test Systems

Bed-of-Nails Testers

Use Case: High-volume PCB production (e.g., consumer electronics).

Features: Dedicated fixtures with spring-loaded probes for rapid testing.

Pair With: Custom test fixtures for board-specific accuracy.

Flying Probe Testers

Use Case: Low-volume, high-mix environments (e.g., prototypes).

Features: Probe mobility for flexible, fixture-free testing.

Boundary Scan (JTAG)

Use Case: Testing complex digital circuits (e.g., BGAs, microprocessors).

Features: Leverages onboard JTAG ports for deep circuit access.

Applications of In-Circuit Testing

Automotive Electronics

Validate Engine Control Units (ECUs) and infotainment systems to meet ISO 26262 safety standards.

Integration: Use hydraulic torque wrench calibration data to test sensor PCBs.

Aerospace & Defense

Ensure avionics PCBs withstand extreme temperatures and vibrations (MIL-STD-883 compliance).

Medical Devices

Test life-critical systems like pacemakers and MRI control boards for 100% reliability.

Consumer Electronics

Detect defects in smartphones, IoT devices, and wearables before mass production.

Panel vs. Omni Antennas: Which to Choose?

| Advantage | Impact |

| Early Defect Detection | Reduces rework costs by up to 80% |

| High Throughput | Tests 10,000+ points per PCB in seconds |

| Data-Driven Insights | Tracks failure trends to optimize manufacturing |

How to Implement ICT Effectively

Step 1: Design for Testability (DFT)

Include test points in PCB layouts for probe access.

Use test probes with <0.5Ω contact resistance.

Step 2: Select the Right Fixture

Bed-of-Nails: Ideal for high-volume runs.

Flying Probe: Best for prototypes or low-volume batches.

Step 3: Integrate with Production Lines

Sync ICT systems with automated assembly lines for real-time feedback.

For tailored setups, contact Petra Carbon’s engineers.

Why Petra Carbon’s ICT Solutions Stand Out

Precision Fixtures: Custom fixtures with board test probes ensure repeatable accuracy.

Global Support: 24/7 technical assistance for Teradyne, Keysight, and Agilent systems.

Scalability: Solutions for startups to Fortune 500 manufacturers.

FAQs About In-Circuit Testing

How does ICT differ from functional testing (FCT)?

ICT checks individual components, while FCT validates the PCB’s operational performance.

What’s the cost of an ICT system?

Varies by complexity—flying probe testers start at

50k;bed−of−nailssystemsrangeupto

50k;bed−of−nailssystemsrangeupto500k.

Can ICT test RF components?

Yes! Pair with RF test fixtures for impedance and signal integrity checks.

At Petra Carbon, we engineer ICT solutions that eliminate manufacturing risks, from prototyping to mass production.

🔗 Contact Us for a consultation or explore our Testing Solutions Hub.

Minimize risks, maximize efficiency!