Virtually the entire Boltite product lineup from Petracarbon is available for rental on a daily, weekly or monthly basis. Petracarbon maintains a large inventory of machines & accessories at our strategically located regional Rental Centers, ready to ship on short notice.

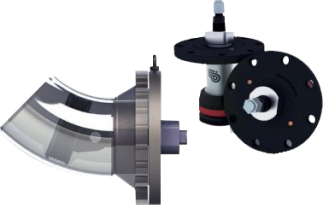

Rental choices include our range of bolt tensioning & torque tools. Renting with petracarbon is a great option for short term usage such as repair projects, scheduled turnarounds & power generation outages. Individually inspected & tested before shipment, Petracarbon rental equipment arrives configured for your exact application.

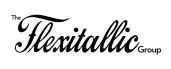

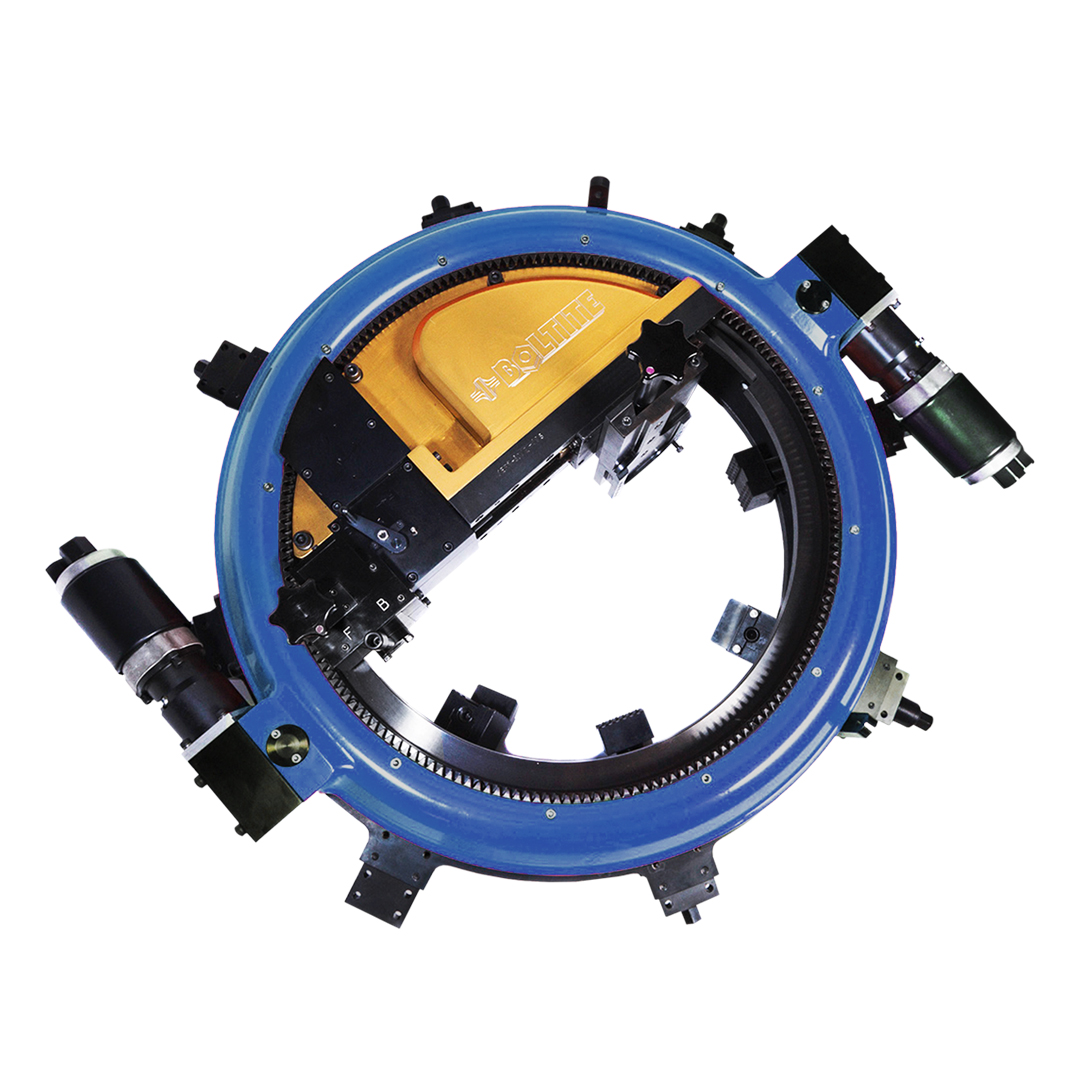

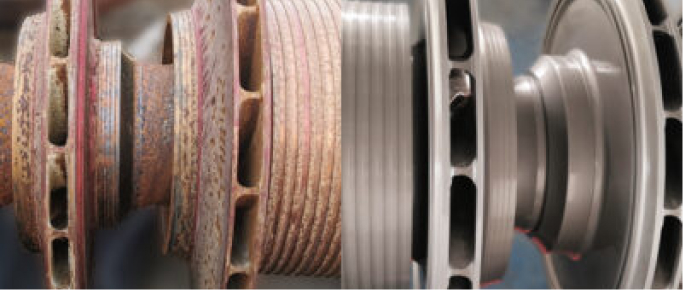

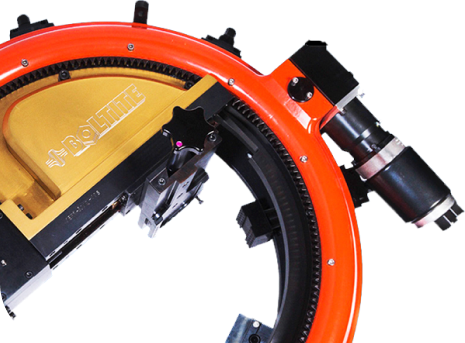

Other Rental choices include our entire line of OD & ID mounted flange facers, O.D. mounted split frame rotating ring pipe cutters, with drive options including electric, hydraulic and pneumatic (depending on model).

Petracarbon is a one-stop engineering solutions provider with comprehensive on-site engineering facilities and capabilities, as well as teams of dedicated and experienced manpower that are available 24 hours a day, seven days a week to design and develop solutions specific to your requirements.

We provide mechanical engineering & machining services for conventional & subsea bolt tensioning, bolt torquing, pipe cutting and beveling, flange facing, milling, drilling and tapping, line boring, and leak sealing operations to a vast range of industries ranging from Power Generation, Petrochemical, Offshore Oil & Gas, Marine, Shipbuilding and Ship Repair, Automotive & Constructions. We own a range of professional and reliable equipment which can meet the requirements for applications in a wide variety of fields. Check out our list of services:

We are proud to partner the following quality industrial suppliers:

Our wide range of products are designed for joint integrity management systems to ensure leak free joints. Besides distributing various quality products from our key partners, Petracarbon registers Boltite as the company’s trademark to its various products.

Petracarbon is dedicated to delivering our clients fast, cost-effective and environmentally friendly industrial cleaning solutions catered to their specific cleaning challenges.

Industrial and manufacturing facilities are subjected to rigorous operating conditions and often require regular maintenance and cleaning in order to ensure maximum production efficiency and adherence to environment, health and safety standards.

As an established company working with Oil and Gas, Shipyard and Petrochemical companies for the past 40 years, Petracarbon understands the unique operating challenges facing our industrial customers. We offer a range of industrial cleaning services – high pressure water jetting, fin fan foam cleaning and chemical cleaning to meet our customers’ requirements.

As the demand for green technologies and solutions increases on a global scale, our industrial cleaning services division added dry ice cleaning as an environment-friendly alternative to conventional industrial cleaning practices.

No matter how difficult the assignment, we are ready to work with you to ensure the best results.

Petracarbon’s primary goal is to promote maximizing efficiency and minimizing downtime on every onsite bolting job. We provide competent, trained and experienced field technicians for controlled torquing, bolt tensioning, and disassembly services for routine maintenance, significant turnarounds, and capital projects for oil & gas, chemical, petrochemical, and oil refining industries.

Our tools are developed in accordance with globally recognized standards such as TUV, ISO, DNV to ensure that leak-free bolting connections are achieved safely and competently with the correct bolt loads.

We have the right bolting solutions for your facility, to provide the controlled bolting results required.

Petracarbon specialty services include both online leak sealing services and hydrostatic weld testing services. We cater to a unique array of devices that will suit your requirement for any job. Our offerings include different types of Flange Weld Testers and torque wrench calibration service, that provide a high level of operational benefits. Petracarbon’s professionally trained staff with state-of-the-art devices ensure high customer satisfaction and ensures continuity in your day to day operations.

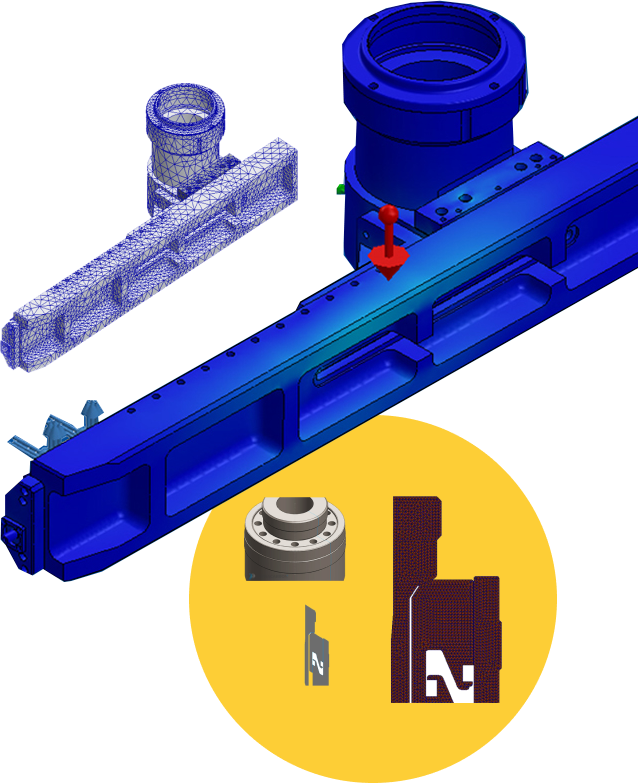

Petracarbon’s consulting engineers have a broad experience base in applying Finite Element Analysis & related methods. Our expertise has been accumulated through years of experience in product design, failure analysis, new product Development and design optimization.

FEA enables designers to better understand how complex geometries respond to applied loads, which may be time consuming or impossible using traditional methods such as hand calculations. It also helps to minimize the risk of part failure in real world conditions by revealing performance issues that may otherwise be overlooked.

With the ability to prototype products rapidly, accurately and safely, costs are reduced with a resulting decrease of lead time to commercialization. The ability to optimize a design also leads to a final product that is robustly designed, at the same time eliminating wastage arising from multiple iterations of physical prototyping and testing.

The ability to model complex parts enables designers to study their behavior in response to real world loading and identifying the weak links in a design. Often, an assembly can fail due to inadequate design of a single component. Therefore it is vital that the designer identifies critically loaded components and ensure they are adequately designed to increase the service life of a product as a whole.

FEA simulations enable product designers to model complex assemblies and subject them to extensive testing virtually. This drastically reduces the number of physical prototypes that need to be made for testing purposes and cuts down on the number of design iterations required to arrive at a viable solution. Most importantly, the safety of the testing process can be enhanced since critically loaded components can be modelled and studied with a high level of accuracy prior to physical prototyping.

Petracarbon execute cold pipe cutting at any given angle, horizontal and vertical pipes whether inland or offshore with cutting range from 2” up to 56” using clamshell pipe cutters.

For large pipe sizes, we can deploy our pipe milling machine which we had severed off cylindrical tank/drum/column of up to 3m in diameter for decommissioning of inland/offshore equipment and during plants shutdown.

Petracarbon also has portable high pressure abrasive waterjet cutting machine that can cut steel plate and/or pipe of various grades/sizes/thicknesses.

Petracarbon strives to have a complete range of products & services to serve the Oil and Gas market from downstream to upstream, offshore to onshore.

Petracarbon is the Asia’s largest manufacturer of bolt tensioning products for the Oil and Petrochemical industry. We are proud to be able to design custom made tools for special applications to solve the bolting needs of our clients.

We provide a range of experience & expertise to address various bolting requirements for flange applications in the power industry. As such, we are proud to design & manufacture pioneering bolting solutions to optimise safety & increase productivity. Our comprehensive range of technology & services supplied to the industry includes torque, tension, on-site machining, on-site training and bolting services.

Our range of subsea bolting tools are made to last and specially designed for the ease of diver usage.