In high-demand industrial and telecom environments, the reliability of receptacles and battery connectors is essential to ensure uninterrupted power and signal integrity. Poorly maintained or improperly selected connectors can lead to intermittent failures, downtime, and costly system inefficiencies.

At Petracarbon, we leverage decades of engineering experience in Singapore to provide practical, actionable guidance on choosing, maintaining, and optimising these critical components. This article explores the challenges, best practices, and field-tested solutions for maintaining contact reliability across industrial and telecom systems.

Understanding Receptacle Performance in High-Demand Applications

Common Challenges in Industrial and Telecom Settings

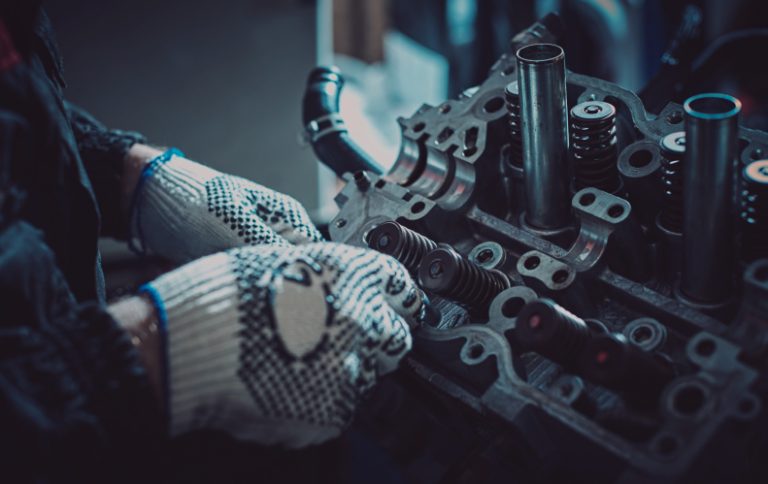

Industrial and telecom systems often expose receptacles and battery connectors to harsh operating conditions. High current loads, frequent mating cycles, and environmental stressors such as vibration, temperature fluctuations, and moisture can significantly impact connector performance.

In RF systems, improper installation of coaxial cables or jumper cables can compromise signal integrity, leading to intermittent connectivity and potential equipment damage. Engineers must account for these factors when selecting and maintaining connectors to ensure long-term reliability.

Consequences of Poor Contact Reliability

Failure to maintain receptacles can result in equipment malfunctions, signal degradation, and unexpected system downtime. In industrial environments, even brief interruptions can halt production lines, while in telecom setups, poor connections may cause communication errors or network instability. Ensuring consistent electrical contact, proper alignment, and regular inspections are therefore critical to avoid these operational risks.

Choosing the Right Receptacle for Your System

Material Selection and Contact Plating

The material composition and plating of a receptacle directly influence conductivity, resistance, and corrosion performance. Copper is widely used for high conductivity, while gold plating provides exceptional corrosion resistance and stable contact over numerous mating cycles.

In high-frequency RF applications, maintaining low contact resistance is crucial to prevent signal loss. Selecting the correct material ensures reliability in both industrial and telecom environments, particularly for battery connectors that must handle fluctuating currents.

Connector Design Considerations

Design factors such as pin density, alignment tolerance, and mechanical robustness play a significant role in contact reliability. Receptacles should be compatible with jumper cables and coaxial cables without excessive insertion force, which could lead to wear over repeated cycles. Modular designs allow easy replacement of worn pins without disassembling the entire system, improving maintenance efficiency and reducing downtime.

Matching Receptacles to Application Needs

Not all connectors are suitable for every application. Engineers must consider the current rating, voltage, and environmental exposure of the system. For example, telecom racks may require connectors with robust shielding to prevent interference, while industrial control panels need high mechanical durability to withstand vibration. Selecting the correct connector ensures safe, reliable, and long-lasting operation.

Maintenance and Inspection for Maximum Reliability

Routine Checks and Cleaning

Regular inspection is vital to maintain receptacle performance. Dirt, oxidation, or mechanical wear can compromise connections, leading to signal degradation or power loss. Non-abrasive cleaning methods, such as compressed air or approved industrial cleaning solutions, can remove debris without damaging delicate contacts. Implementing a scheduled inspection routine ensures that connectors remain fully functional throughout their service life.

Replacement and Lifecycle Management

Over time, receptacles may reach the end of their useful life due to repeated mating cycles, material fatigue, or environmental exposure. Tracking the number of insertion/removal cycles and monitoring performance metrics such as contact resistance helps determine optimal replacement intervals. Proactively replacing connectors before failure reduces the risk of downtime and costly repairs.

Troubleshooting Intermittent Failures

Even properly maintained connectors can experience intermittent failures if installation or handling is improper. Common issues include misaligned pins, insufficient mating force, or damaged insulation. Field engineers should use diagnostic tools to measure continuity, resistance, and signal quality to identify and correct issues without disassembling the entire system.

Ensuring Optimal Performance with Jumper Cables and Coaxial Connections

Proper Mating Techniques

Correctly mating jumper cables and coaxial connectors is critical for maintaining long-term reliability. Misalignment or excessive insertion force can damage contacts or create uneven pressure, reducing the lifespan of the connector. Field engineers should ensure pins and sockets are fully aligned before applying force and avoid excessive bending or twisting of cables during installation.

Signal Integrity Considerations

In RF systems, maintaining impedance consistency is essential to prevent reflections, crosstalk, or attenuation. Careful routing of coaxial cables, proper termination, and using connectors with precise mechanical tolerances ensure signal integrity is preserved across the system. This is particularly important in telecom applications, where even minor deviations can affect network performance.

Practical Tips from Field Engineers

Inspection Checklists

Field engineers often rely on structured checklists to ensure no critical inspection points are missed. This includes verifying pin integrity, checking for corrosion, ensuring proper mating force, and testing signal continuity. Using a checklist improves efficiency and reduces the likelihood of connector failure during operation.

Best Practices for Installation and Handling

Correct handling of receptacles and battery connectors reduces wear and extends service life. Tips include avoiding excessive insertion/removal cycles during testing, using protective covers when connectors are not in use, and maintaining clean contact surfaces.

Documentation and Traceability

Maintaining records of inspection, maintenance, and replacement schedules helps teams track connector performance over time. Documentation ensures contact reliability is maintained and provides a reference for troubleshooting or compliance audits.

Maximising System Reliability with Quality Receptacles

Selecting the right receptacles, performing regular inspections, and following proper installation practices are critical to maintaining contact reliability in industrial and telecom systems. Properly matched connectors, combined with careful handling of jumper cables and coaxial connections, ensure long-term operational efficiency.

📌 For expert guidance on battery connectors, receptacles, and high-performance RF systems, contact Petracarbon today to optimise your system’s reliability and performance.