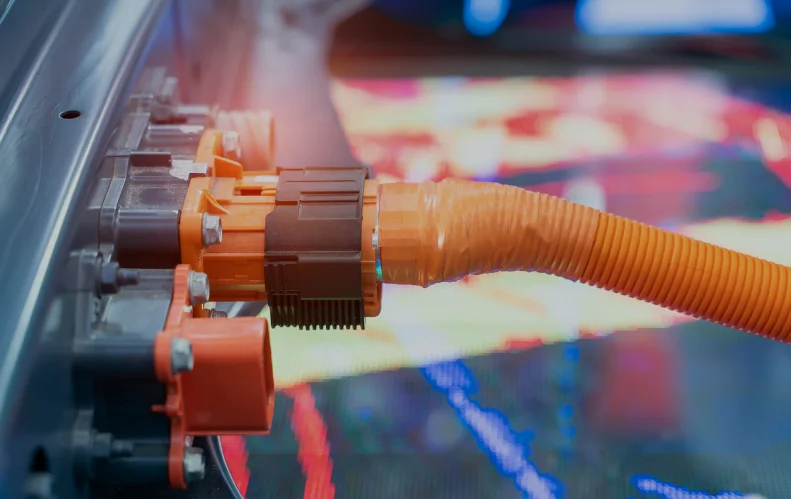

In industrial and telecom applications, stable power transmission depends heavily on the reliability of battery connectors and receptacles. When these components start to degrade, the impact ripples across systems, causing voltage drops, signal interruptions, and costly downtime.

At Petracarbon, our teams have encountered and solved numerous field issues linked to connector degradation. This article offers practical insights into diagnosing and resolving power delivery issues in connectors, focusing on measurable factors like contact resistance, insertion loss, and connector wear.

Understanding the Root Causes of Power Delivery Issues

Why Battery Connectors and Receptacles Fail in the Field

Failures in battery connectors and receptacles rarely occur suddenly, they usually evolve through gradual wear and environmental stress. Common causes include:

- Oxidation or corrosion from humidity or contamination.

- Loss of spring force in the contact pins due to mechanical fatigue.

- Misalignment from repeated insertions or poor mating geometry.

- Temperature cycling that loosens mechanical fits over time.

These factors lead to subtle but measurable degradation in performance. Voltage drops, heat buildup, or intermittent current flow are often early warning signs that contact resistance is rising beyond safe limits.

The Role of Contact Resistance and Connector Wear

In an ideal connector, resistance across the contact interface remains stable. Over time, however, surface wear and contamination cause contact resistance drift, a slow increase that can affect power delivery efficiency. Once resistance increases even a few milliohms, energy is lost as heat, leading to compounding failure risks.

| Issue | Typical Range | Engineering Impact |

| Contact resistance drift | 5–20 mΩ increase | Heat generation, voltage drop |

| Spring force loss | 10–30% reduction | Inconsistent contact pressure |

| Surface oxidation | N/A | Electrical arcing, signal loss |

Field Testing and Diagnosis

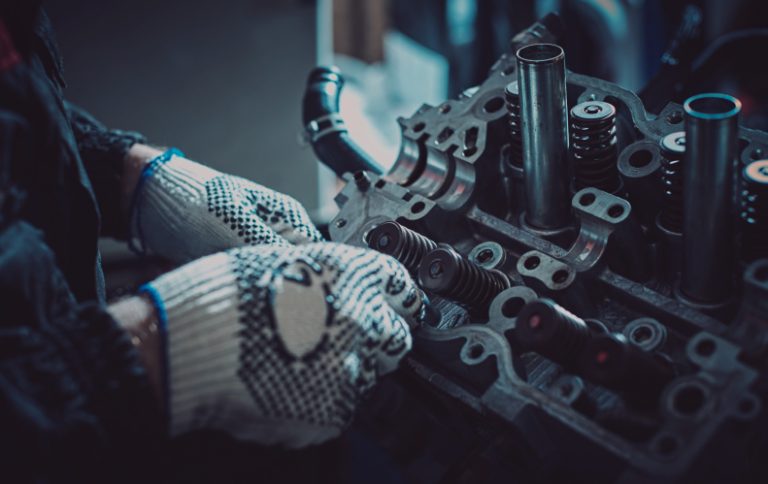

Visual and Mechanical Inspection Techniques

The first step in troubleshooting a battery connector or receptacle is physical examination. Engineers typically check for:

- Bent or recessed pins

- Worn plating or discolouration (a sign of arcing)

- Loose housings or misaligned terminals

- Dirt, debris, or oil contamination

Using magnification or a microscope helps detect micro-cracks or plating fatigue that may not be visible to the naked eye.

Measuring Electrical Performance

Electrical testing complements physical inspection. Field engineers measure key performance parameters:

| Parameter | Tool | Acceptable Range |

| Contact resistance | Micro-ohmmeter | < 10 mΩ (clean contact) |

| Insertion loss | Network analyzer | < 0.5 dB at rated frequency |

| Continuity | DMM / Multimeter | No intermittent readings |

An increase in insertion loss often correlates with connector wear or poor plating integrity. Data logging helps identify progressive deterioration, allowing preventive replacement before failure.

Common Power Delivery Problems and Solutions

High Contact Resistance

High Contact Resistance

When troubleshooting high contact resistance, engineers should start by comparing the measured resistance against the component’s baseline or manufacturer’s rating. Elevated readings often indicate oxidation, poor spring tension, or accumulated debris. The table below highlights key failure modes and corrective measures:

| Symptom | Root Cause | Recommended Fix |

| Voltage drop under load | Oxidized surfaces | Clean or replace contact surfaces |

| Local heating | Weak spring tension | Replace receptacle springs |

| Intermittent connection | Mechanical fatigue | Replace connector pair |

Excessive Insertion Loss

Excessive Insertion Loss

Excessive insertion loss can be caused by loose terminations or degraded plating. In such cases:

- Verify cable termination torque and mechanical stability.

- Inspect plating for delamination or cracks.

- Replace worn or low-quality connectors.

Low insertion loss ensures clean energy transfer, a vital factor in high-reliability telecom systems.

Improving Reliability Through Engineering Controls

Material and Coating Considerations

Selecting the right material for a battery connector or receptacle has a direct impact on reliability.

| Material | Benefit |

| Gold plating | Low contact resistance, corrosion protection |

| Silver plating | High conductivity, cost-efficient |

| Nickel underlayer | Prevents diffusion and base metal corrosion |

Surface coatings mitigate oxidation and extend connector life, especially under high humidity or vibration.

Connector Design Factors That Affect Longevity

Durability depends on more than just material, it’s also about geometry. Key design features include:

- Mating alignment to reduce contact wear.

- Retention features to maintain secure engagement.

- Controlled contact pressure to balance force and wear.

Minor design improvements often yield measurable gains in power delivery consistency.

Preventive Maintenance and Field Replacement Strategy

Scheduled Inspection Intervals

Regular maintenance helps avoid costly failures. A sample inspection schedule:

| Usage Type | Inspection Interval | Action |

| Industrial (daily cycle) | Every 3 months | Inspect and clean connectors |

| Telecom (moderate use) | Every 6 months | Verify insertion loss and retention force |

| Backup or static systems | Annually | Replace if contact resistance >10 mΩ |

Tracking contact resistance and insertion loss trends helps predict wear before downtime occurs.

Replacement vs Refurbishment

In field operations, engineers must decide when to clean, repair, or replace connectors:

- Replace when there’s mechanical deformation or plating wear-through.

- Refurbish if light oxidation or debris is the main issue.

- Never reuse connectors showing arcing or heat damage.

These guidelines improve reliability while managing maintenance costs.

Testing Standards and Quality Assurance

Relevant Testing Standards

Industry standards ensure connector reliability under real conditions:

- IEC 60512 – Tests for contact resistance and vibration.

- MIL-DTL-55302 – Connector durability and mating cycle performance.

- IPC-9701 – Reliability of soldered connections under stress.

Petracarbon integrates these benchmarks into its manufacturing and testing procedures, ensuring each battery connector and receptacle meets industrial expectations.

Recording and Validating Test Data

Data-driven maintenance is critical. Tracking insertion loss and contact resistance variations over time provides insights into wear trends. Using digital records allows predictive analytics to forecast connector lifespan.

Field Lessons from Petracarbon Engineers

Common Troubleshooting Mistakes

Common Troubleshooting Mistakes

Even experienced engineers can overlook small but critical factors during connector maintenance. Here are some of the most common troubleshooting mistakes seen in the field:

- Over-tightening fasteners, which distorts connector housings.

- Neglecting to test connectors under actual load or temperature.

- Ignoring microscopic oxidation, which accelerates contact resistance rise.

Practical Insights from Industrial Cases

Practical Insights from Industrial Cases

In one telecom case, early detection of rising contact resistance prevented a major base station failure. Another battery manufacturing client reduced unplanned downtime by tracking connector wear and setting proactive replacement thresholds.

Ensuring Long-Term Power Reliability

Reliable battery connectors and receptacles are vital to consistent power delivery. By monitoring contact resistance, managing insertion loss, and adhering to preventive maintenance schedules, engineers can dramatically reduce equipment failure rates while improving operational uptime. For in-depth connector diagnostics, fixture calibration, or replacement solutions, contact our engineering team at Petracarbon.

📌 Need expert assistance? Petracarbon’s team in Singapore provides connector testing, analysis, and tailored solutions for critical power systems. Reach out today to ensure your systems run efficiently and safely.