The Need for Efficient Testing in Electronics Manufacturing

In electronics manufacturing, efficient and accurate testing is essential to ensure high product quality and reduce production errors. One of the most effective methods for testing printed circuit boards (PCBs) is the in-circuit test (ICT). When combined with a high-performance fixture and trusted systems like the Keysight i3070 and Keysight i1000, ICT becomes a powerful tool for diagnosing faults and ensuring product reliability.

In this guide, we’ll explore the key elements of a high-performance fixture, the benefits of automated in-circuit testing, and how Keysight-compatible solutions can optimize your manufacturing workflow.

Key Elements of a High-Performance Fixture

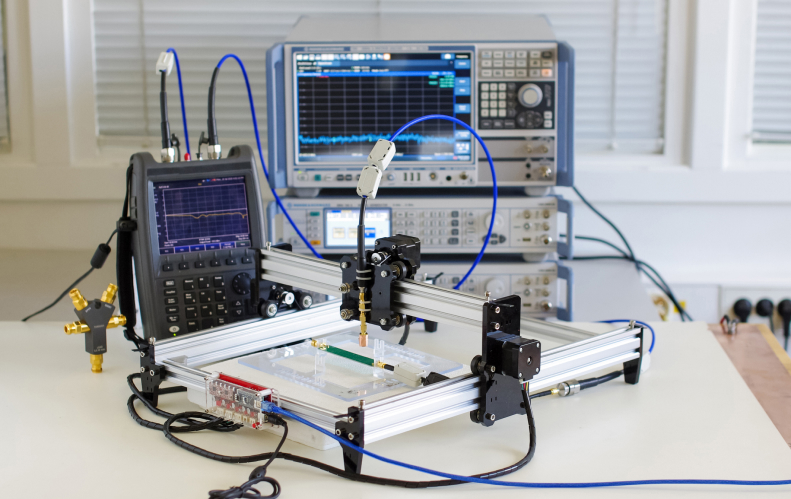

A reliable fixture is the foundation of any successful in-circuit test. It ensures that the PCB is securely positioned and that test probes make accurate contact with the appropriate test points.

- Precision Alignment: Ensures accurate positioning of the PCB for consistent test results.

- Durable Materials: Built to withstand thousands of test cycles without degradation.

- Flexibility: Adaptable to different PCB designs and sizes.

- Ease of Maintenance: Allows for quick replacement of worn-out probes or parts.

Using a well-designed fixture improves test accuracy, reduces setup time, and enhances the overall efficiency of the in-circuit testing process.

Benefits of Automated In-Circuit Testing

Automated in-circuit test systems offer significant advantages over manual testing methods. They provide a fast, reliable, and repeatable way to ensure the quality of PCBs during high-volume production.

Benefits of Automated ICT:

- Speed and Efficiency: Reduces test cycle times, allowing for faster throughput.

- Durability: Capable of withstanding repeated connections and disconnections.

- Material Quality: Use of corrosion-resistant metals for long-lasting performance.

Integrating automated ICT with a robust fixture ensures that manufacturers can meet quality standards while maintaining production efficiency.

Compatibility with Keysight Systems for Reliability

Keysight is a leading provider of automated test equipment known for its reliability and precision. Ensuring your fixtures are compatible with Keysight systems enhances the efficiency and accuracy of your in-circuit testing process.

Why Choose Keysight-Compatible Fixtures:

Coaxial probes and spring contact probes are essential for achieving precision in high-frequency and standard circuit testing. Each type offers unique benefits that improve overall test performance.

- Reliable Performance: Keysight systems are known for their accuracy and durability.

- Seamless Integration: Fixtures designed for Keysight systems ensure smooth operation and setup.

- Advanced Software: Provides powerful diagnostics and reporting tools to streamline the testing process.

Using fixtures that are specifically designed for Keysight systems ensures you get the most out of your in-circuit test equipment, improving overall workflow and reducing downtime.

Choosing Between the i3070 and i1000 Models

When selecting a Keysight system for in-circuit test applications, two popular options are the i3070 and i1000 models. Each offers unique benefits depending on your testing needs.

Keysight i3070:

- High-Speed Testing: Ideal for large-scale, high-volume production.

- Comprehensive Fault Detection: Advanced diagnostics for complex PCB designs.

- Scalability: Supports multiple fixtures and test configurations.

Keysight i1000:

- Cost-Effective: A budget-friendly option for small to medium-scale operations.

- Flexible Configuration: Adaptable to various PCB designs and testing requirements.

- Ease of Use: User-friendly interface for quick setup and execution.

Choosing the right model depends on your production volume, budget, and testing complexity. Both the i3070 and i1000 deliver reliable performance when paired with high-quality fixtures.

Optimizing Workflows with the Right Fixtures

Efficient PCB testing relies on the combination of in-circuit test systems and high-performance fixtures. By using Keysight-compatible solutions like the i3070 and i1000 models, manufacturers can streamline their testing processes, reduce errors, and enhance productivity. Investing in quality fixtures ensures accurate diagnostics and long-term reliability, helping you meet production goals and maintain high standards.

For expert advice on choosing the right in-circuit test fixtures, visit Petracarbon or Contact Us to learn more.