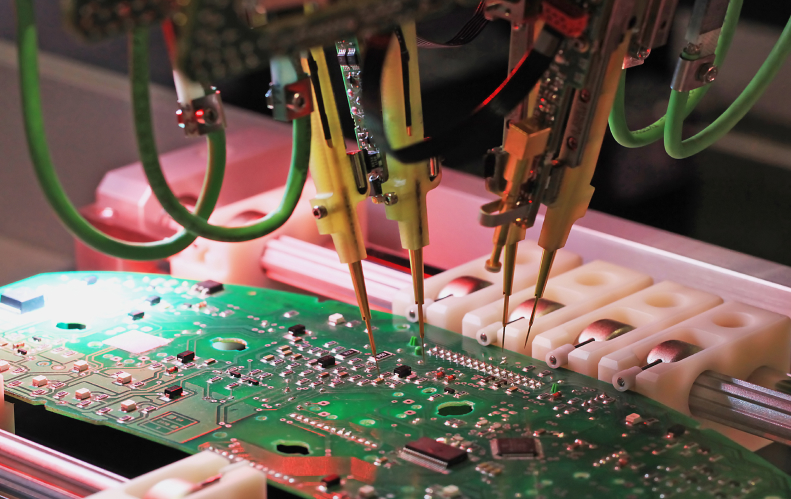

Board test probes are essential tools in electronics manufacturing, enabling engineers to validate electrical connections, detect defects, and ensure compliance in printed circuit boards (PCBs). At Petra Carbon, we specialize in high-performance test probes designed for durability, repeatability, and seamless integration with leading test systems like Teradyne and Keysight. This guide explores board test probe types, applications, and how Petra Carbon empowers industries to achieve zero-defect production.

What Is a Board Test Probe?

A board test probe is a spring-loaded contact pin used to establish temporary electrical connections between test equipment and PCB test points. These probes are critical for in-circuit testing (ICT), functional testing (FCT), and flying probe validation, ensuring components like resistors, capacitors, and ICs meet design specifications.

Key Features of Petra Carbon’s Test Probes:

Current Rating: 0.5A to 30A+ for low-power and high-current applications.

Durability: 100,000+ mating cycles with minimal contact resistance drift.

Compatibility: Works with Teradyne 3070 and Keysight ICT systems.

Explore our test probe catalog for industry-specific solutions.

Types of Board Test Probes

Spring-Loaded (Pogo) Probes

Use Case: High-density ICT and bed-of-nails fixtures.

Features:

– Plunger-style design with 0.5–5mm travel.

– Gold-plated tips for low contact resistance (<50mΩ).

Pair With: Test fixtures for PCB validation.

Coaxial Probes

Use Case: RF and high-frequency signal testing (e.g., 5G modules, antennas).

Features:

– 50Ω/75Ω impedance matching.

– SMA/BNC connectors for seamless integration with network analyzers.

High-Current Probes

Use Case: Validating power delivery networks (PDNs) in EV battery systems.

Features:

– 30A+ continuous current handling.

– Tungsten carbide tips for wear resistance.

Microfabricated Probes

Use Case: Wafer-level testing and MEMS device validation.

Features:

– Tip diameters as small as 10μm.

– Compatible with test sockets for IC testing.

Applications of Board Test Probes

In-Circuit Testing (ICT)

Detect opens, shorts, and component value deviations in PCBs.

Integration: Petra Carbon’s probes work with Teradyne ICT systems for high-throughput validation.

Functional Testing (FCT)

Validate PCB operation under simulated real-world conditions (e.g., power cycling).

RF Testing

Measure impedance, S-parameters, and signal integrity in 5G/Wi-Fi modules.

Automotive Electronics

Test ADAS sensors and EV charging systems for ISO 26262 compliance.

How to Select the Right Test Probe

| Factor | Consideration |

| Current/Voltage | Match probe specs to DUT requirements (e.g., 30A for PDN testing). |

| Frequency Range | Use coaxial probes for RF (>1 GHz) applications. |

| Tip Geometry | Chisel, crown, or spear tips for varied PCB pad types. |

Pro Tip: Pair probes with flange alignment tools for precise fixture assembly.

Why Petra Carbon’s Test Probes Excel

Precision Engineering: Probes are validated using in-circuit test systems for micron-level accuracy.

Custom Solutions: Tailored tip geometries, plating (gold/nickel), and spring forces.

Global Compliance: Meets IPC, MIL-STD-202, and RoHS standards.

FAQs About Board Test Probes

How do I clean test probes?

Use isopropyl alcohol and a lint-free cloth. Replace probes showing >10% resistance drift.

Can probes handle high-temperature environments?

Yes! Our high-temp probes operate at -55°C to +175°C.

Do you offer probes for flexible PCBs?

Absolutely—soft-tip probes prevent damage to delicate flex circuits.

At PetraCarbon, we engineer test probes to deliver precision in the most demanding environments, from automotive labs to 5G production lines.

🔗 Contact Us for expert guidance or explore our Test Probe Catalog.

Precision in every probe!