Connector receptacles are essential interfaces in electrical and RF systems, providing secure, low-resistance connections between cables, PCBs, and devices. At Petra Carbon, we engineer high-performance receptacles designed to withstand extreme conditions in industries like aerospace, automotive, and telecommunications. This guide explores receptacle types, critical applications, and how Petra Carbon’s solutions deliver unmatched durability and precision.

What Is a Connector Receptacle?

A connector receptacle is the fixed (female) component of a connector pair, designed to mate with a plug (male) to establish electrical or signal continuity. Unlike RF connectors, which prioritize signal integrity, receptacles focus on mechanical stability, environmental resistance, and ease of mating in high-stress applications.

Key Features of Petra Carbon’s Receptacles:

Materials: Stainless steel, phosphor bronze, or thermoplastic housings.

Environmental Ratings: IP67/IP69K for dust/water resistance; MIL-STD-810G for shock/vibration.

Current Handling: 5A to 200A+ for low-power sensors to industrial machinery.

Explore our connector solutions catalog for industry-specific designs.

Types of Connector Receptacles

RF Receptacles

Use Case: Antennas, base stations, and satellite systems.

Features:

50Ω/75Ω impedance matching.

SMA, N-type, or TNC terminations.

Pair With: Coaxial cables for minimal signal loss.

Power Receptacles

Use Case: EV charging ports, industrial motor controls.

Features:

– Gold-plated contacts for low resistance.

– Locking mechanisms to prevent accidental disconnection.

PCB Mount Receptacles

Use Case: Secure board-to-board or cable-to-PCB connections.

Integration: Compatible with test fixtures for automated validation.

Hybrid Receptacles

Use Case: Combine power, signal, and data in a single interface (e.g., robotics).

Features: Mixed contacts for power (30A) and high-speed data (USB 3.0, Ethernet).

Applications of Connector Receptacles

Aerospace & Defense

Secure avionics connections in fighter jets and UAVs, resistant to -55°C to +200°C temperatures.

Compliance: Meets MIL-DTL-38999 for harsh environments.

Electric Vehicles (EVs)

High-current receptacles for battery management and charging systems.

Safety: Flame-retardant materials meet UL 94V-0 standards.

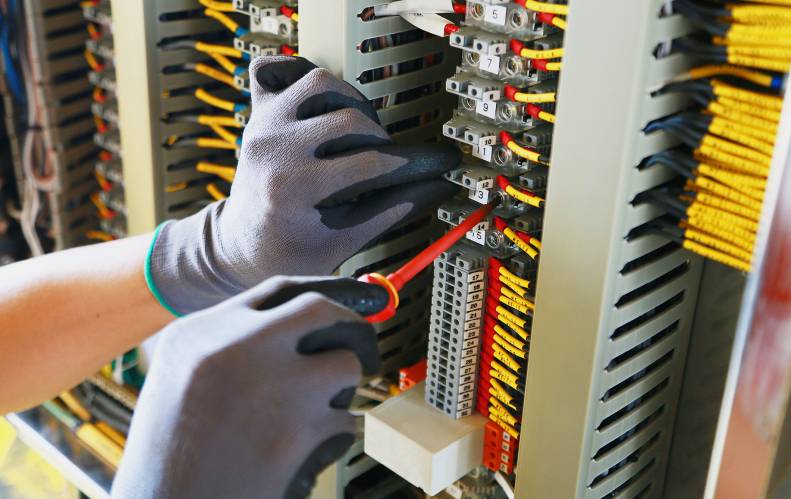

Industrial Automation

Connect sensors, PLCs, and hydraulic torque wrenches in EMI-heavy factories.

Telecommunications

Fiber-optic and RF receptacles for 5G base stations and data centers.

How to Select the Right Receptacle

| Factor | Consideration |

| Environmental Needs | IP ratings, temperature range, and vibration resistance. |

| Electrical Specs | Current/voltage rating, signal type (analog/digital/RF). |

| Mating Cycles | Choose gold-plated contacts for 10,000+ cycles. |

Pro Tip: Use flange alignment tools for precise installation in tight spaces.

Why Petra Carbon’s Receptacles Excel

Precision Engineering: Receptacles are tested using Teradyne ICT systems for contact integrity.

Customization: Adjustable pin layouts, plating options, and housing colors.

Global Standards: Compliant with IEC, ISO, and RoHS directives.

FAQs About Connector Receptacles

What’s the difference between a receptacle and a header?

Receptacles are female connectors; headers are male PCB-mounted pins.

Can receptacles be repaired if damaged?

Replacements are recommended, but contacts can sometimes be reconditioned with test probes.

Do you offer EMI-shielded receptacles?

Yes! Our RF and hybrid receptacles include conductive gaskets for EMI suppression.

At PetraCarbon, we engineer receptacles to thrive in the harshest conditions, from aerospace rigors to industrial automation.

🔗 Contact Us for custom designs or explore our Connector Solutions Catalog.

Engineered for extremes!