Test sockets are critical interfaces in semiconductor manufacturing, providing temporary electrical connections between integrated circuits (ICs) and test equipment. At Petra Carbon, we design durable, high-precision test sockets that ensure accurate validation of ICs across industries like automotive, aerospace, and consumer electronics. This guide explores test socket types, applications, and how Petra Carbon delivers solutions for zero-defect production.

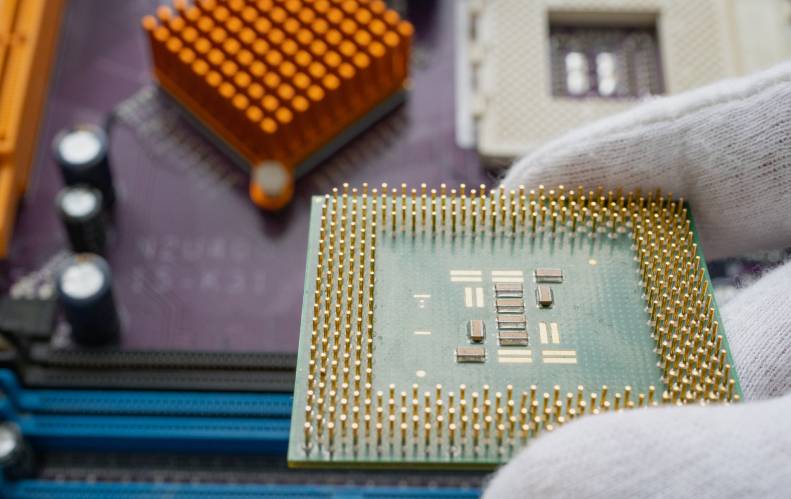

What Is a Test Socket?

A test socket is a electromechanical interface that holds an IC during testing, enabling electrical validation without permanent soldering. Unlike board test probes, sockets are tailored for specific IC packages (e.g., BGA, QFN) and testing phases (e.g., burn-in, functional testing).

Key Features of Petra Carbon’s Test Sockets:

Cycle Life: 100,000+ insertions with minimal contact resistance drift.

Temperature Range: -55°C to +200°C for burn-in and thermal testing.

Compatibility: Supports Teradyne, Keysight, and Advantest handlers.

Explore our testing equipment catalog for socket-ready solutions.

Types of Test Sockets

Burn-In Sockets

Use Case: Stress-testing ICs at extreme temperatures.

Features:

– High-current pins (up to 5A per contact).

– Material: High-temperature thermoplastics (PEEK, LCP).

Functional Test Sockets

Use Case: Validating IC performance in end-use conditions.

Pair With: Test probes for signal integrity analysis.

RF/Wafer-Level Sockets

Use Case: Testing RFICs and mmWave devices up to 110 GHz.

Features:

– 50Ω impedance matching.

– Low insertion loss (<0.5dB at 40 GHz).

Vertical/Clamshell Sockets

Use Case: High-speed automated testing (10,000+ UPH).

Integration: Compatible with Teradyne handlers.

Applications of Test Sockets

Semiconductor Manufacturing

Validate CPUs, GPUs, and memory chips (DDR5, LPDDR5X) pre-packaging.

Automotive Electronics

Test ADAS sensors and EV power modules for ISO 26262 compliance.

Aerospace & Defense

Ensure MIL-STD-883 compliance for radiation-hardened ICs.

Medical Devices

Validate implantable device ICs under biocompatibility standards.

How to Select the Right Test Socket

| Factor | Consideration |

| IC Package Type | BGA, QFN, LGA, or WLCSP-specific designs. |

| Signal Type | RF, high-speed digital, or mixed-signal. |

| Handler Compatibility | Match socket footprint to test equipment. |

Pro Tip: Use flange alignment tools for precise socket installation on test boards.

Why Petra Carbon’s Test Sockets Excel

Precision Engineering: Sockets tested with in-circuit systems for <10mΩ contact resistance.

Custom Solutions: Tailored pin layouts, materials, and actuation mechanisms.

Global Compliance: Meets JEDEC, IPC, and RoHS standards.

FAQs About Test Sockets

How often should test sockets be replaced?

Replace after 100,000 cycles or if contact resistance exceeds 10% of initial values.

Can sockets handle fine-pitch ICs?

Yes! We offer sockets for pitches down to 0.3mm (e.g., micro-BGA).

Do you provide sockets for prototype testing?

Absolutely—3D-printed prototypes available in 5–7 business days.

At PetraCarbon, we engineer test sockets to ensure precision in the most demanding environments, from semiconductor fabs to automotive labs.

🔗 Contact Us for custom designs or explore our Test Socket Catalog.

Precision that performs!