The Joint Integrity Management Program provided by Petracarbon’s PSI Services team is aimed at helping our clients in the oil and gas, and Chemical industries monitor, maintain, and manage their flanges in order to achieve optimum health, safety, and operational efficiency standards.

Importance of Joint Integrity

Reduced risk of leaks, longer life for joints, greater levels of materials reuse, and traceable results all add up to enhanced plant integrity, enhanced plant reliability, and reduced through-life cost. This can be summarised as follows:

The main elements of our Joint Integrity Management program are as follows:

Regular maintenance is the key to preventing dangerous leaks and unplanned production shutdowns from occurring. Petracarbon has been providing specialist bolting solutions for the Oil & Gas, Shipping & Marine and other industrial applications since 1982.

In addition to equipment sales and rental, we also provide on-site services such as bolt tensioning, bolt torquing, flange facing and cold pipe cutting to service bolted joints. Done in the correct manner, these maintenance activities contribute towards reducing the risk of pressure plant leaks to atmosphere as well as unplanned production downtime that can be hazardous and costly.

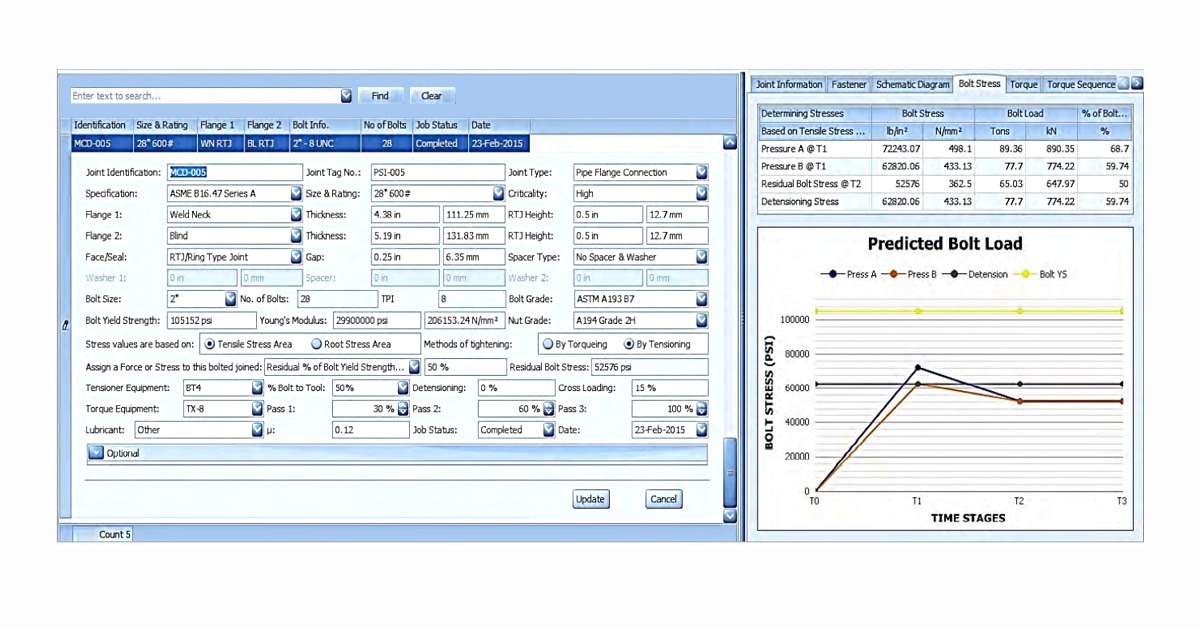

For facilities with numerous flanges, it can be tough to keep track of the installation records, maintenance status and other historical information related to the flanges. At times, the amount of paperwork can be overwhelming and having only physical records puts it at risk of being misplaced or even unintentionally destroyed.

Maintaining the information in a flange management software helps to ensure continuity and accuracy in data recording and can be crucial for large facilities and big maintenance projects.

Ideal for use by bolting service and/or plant maintenance companies who would like to automatically compute bolting calculations and keep track of maintenance data in a single system, implementing the PSI-JIM system will also make the task of generating bolted joint tightening data sheets and summary reports to end clients faster and easier to manage.

Our software is created based on Guidelines for Pressure Boundary Bolted Flange Joint Assembly, ASME PCC-1-2000 and Guidelines for the management of the integrity of bolt joints for pressurised systems – 2nd Edition. It is compliant with the following industry standards:

Flange tagging can be included as part of our project services scope in order to ensure safety protocols are properly adhered to and for important joint information to be easily identified. Our customized flange tags are made weatherproof in order to withstand the industrial conditions the flanges are subjected to daily.

What are bolt protection caps?

These screw-on metal caps are specially designed to be fitted onto the bolts as additional protection against corrosion and thread damage. Bolt protection end caps can be deployed for critical joints to extend the lifespan of bolts and nuts and also contributes to easier maintenance work in future.

Features: