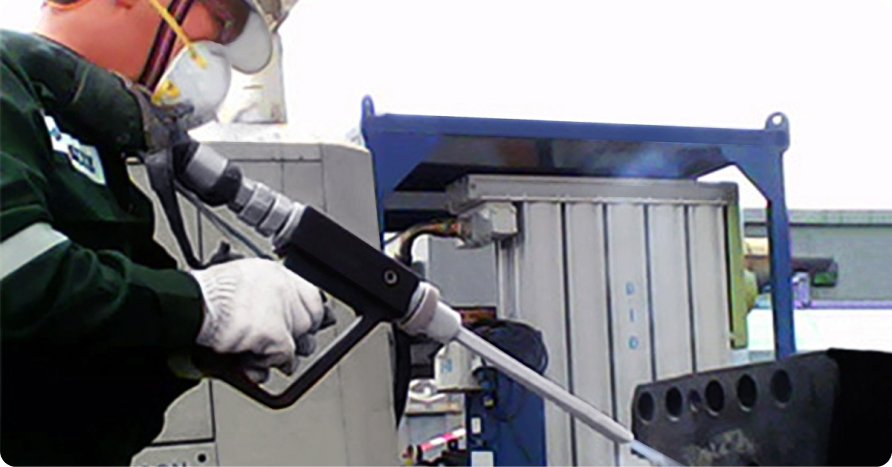

Dry Ice Blasting is a method similar to media blasting where garnet, glass beads or soda are carried by the compressed air stream and directed at high velocity through a nozzle towards the object. However, in the dry ice blasting method instead of abrasive media, dry ice (solid CO2) pellets are used. Petracarbon can deliver real benefits to your company. The operational efficiency of dry ice blasting can be beneficial to many different sectors, such as:

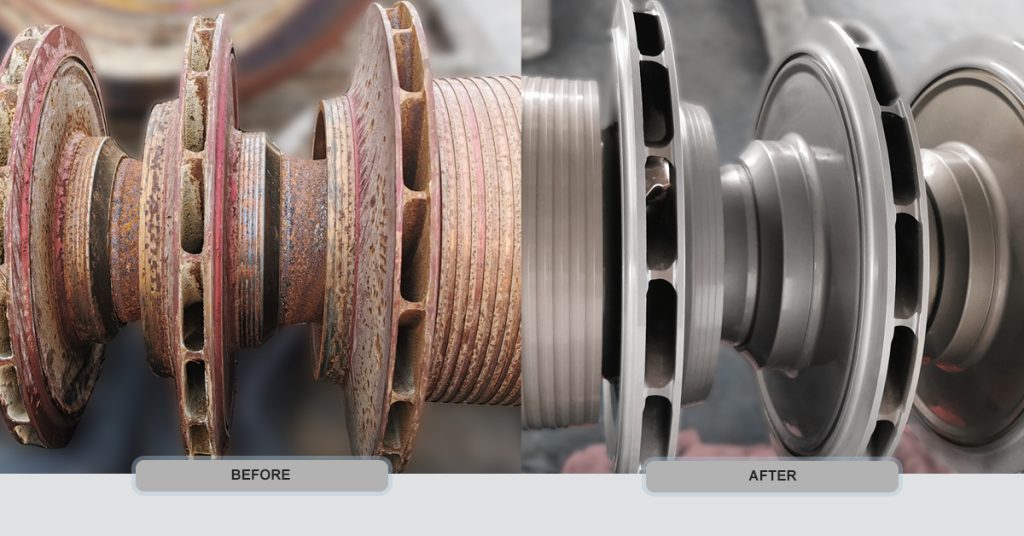

Dry Ice Blasting can be used to remove a wide variety of production residues and accumulated deposits such as carbon, various oxides, salts, rust and corrosion, release agents, chemical deposits, grease/oils, bio-films, adhesives, polymers, paints and coatings, powders, chemical spills

Dry Ice Cleaning is a novel technology well suited to a diverse range of applications found in most of the industrial sectors. It is an environmentally friendly alternative to conventional industrial cleaning practices and in recent years has seen rapid expansion on a global scale owing to its advantages.

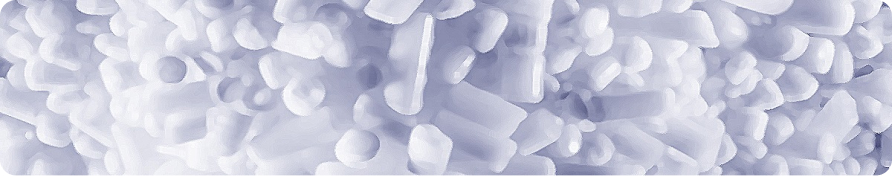

Dry Ice is the solid phase of Carbon Dioxide (CO2) and is produced through extrusion process by a dry ice pelletizer machine. Liquid CO2 is injected into a cylinder where it flashes into CO2 snow and CO2 gas. Snow is then compressed by a piston and extruded through a die plate forming long strands which upon falling into the storage container break to form rice like pellets. The diameter of dry ice can be 3mm, 9mm or 16mm. For cleaning the 3mm size is used.

Size: d=3mm Hardness: 1.5-2 Mohs Temeperature: -78.5 Celsius, Characteristics: colourless, odourless, non-flammable, does not contain water, non-conductive

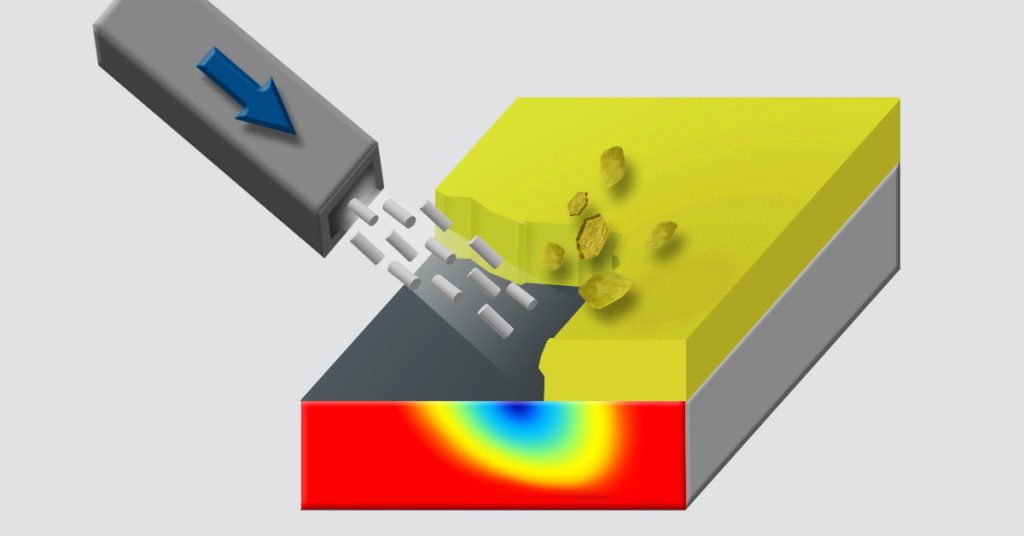

The process is similar to traditional media blasting, however, instead of using hard abrasives such as grit, slag or glass/plastic beads, it employs the power of solid carbon dioxide (CO2) pellets. They are carried by a stream of compressed air and directed at high velocity through a nozzle towards the contaminant layer.

The differences between the two methods is: immediately upon impacting the object, the dry ice pellets sublimate into CO2 gas; no surface profile is created, usually there is no increase in the surface temperature, no peening effect and mechanical stress.

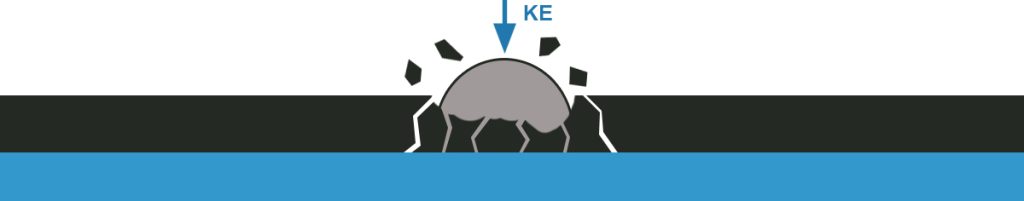

The speed and mass of the dry ice pellets delivered to the surface of the contaminant through compressed air generate kinetic energy which is transformed into cleaning force.

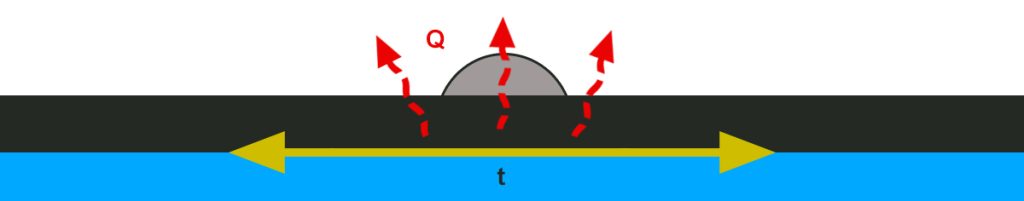

The sudden local cooling generates high shear stress. The bond between the contaminant layer and substrate is loosened significantly which accelerates the removal process.

The dry ice pellets sublimate into gas upon hitting the surface. The gas expands to nearly 800 times the volume of the pellet in a few milliseconds thus producing”Micro-explosions”.

Dry ice blasting helps to reduce shut-down time as many types of equipment can be cleaned on-site without disassembly, while hot and even when the machinery is still in operation. Less offline time means increased production time resulting in better revenue.

Petracarbon is a diversified engineering company headquartered in Singapore. It traces its roots back to 1982 and has now grown to having operations in 5 countries with over 10 locations.