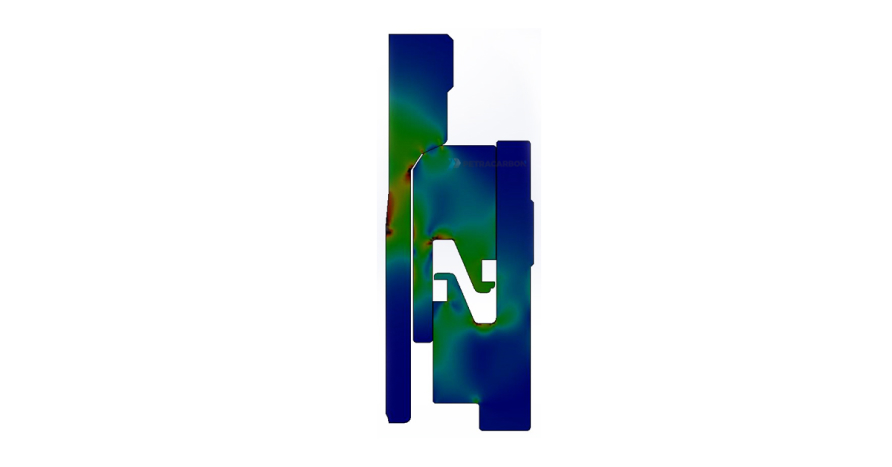

Petracarbon’s consulting engineers have a broad experience base in applying Finite Element Analysis and related methods. Our expertise has been accumulated through years of experience in product design, failure analysis, new product Development and design optimization.

Our consulting engineers have extensive application experience in the following areas:

• Structural Analysis

• Thermal Analysis

• Design Optimization

• New Product Development

• Part optimization

• Pressure Vessel analysis

• Frequency response study

• Fatigue Analysis

• Drop Testing

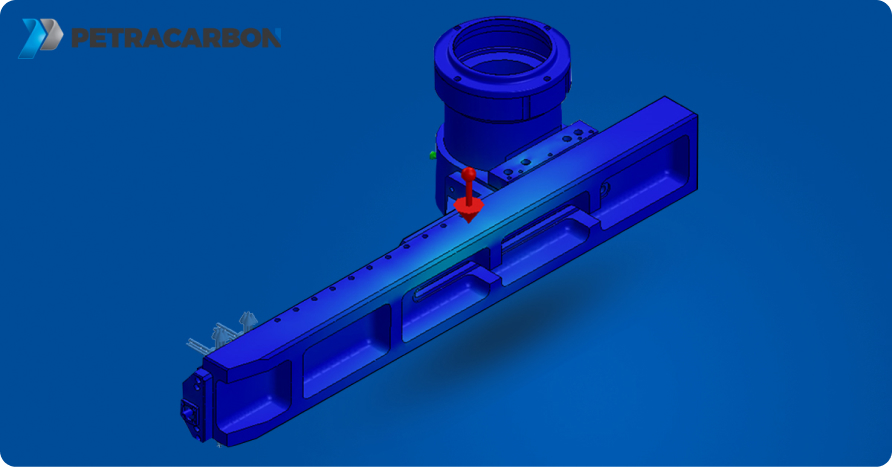

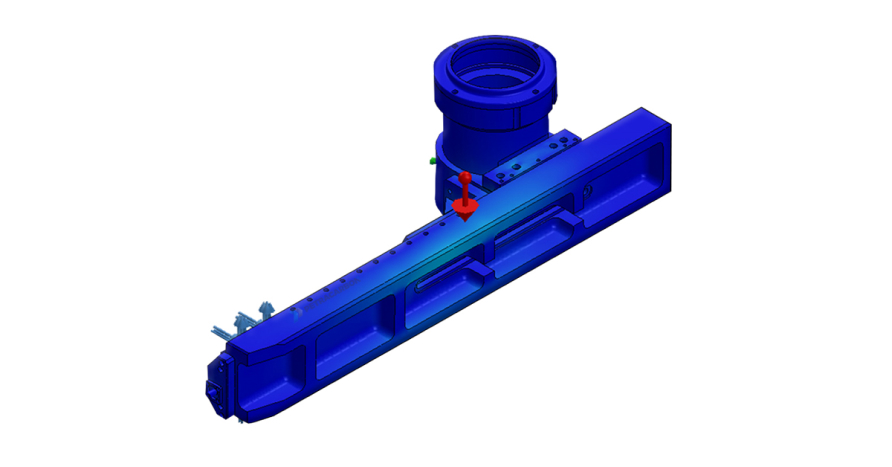

FEA enables designers to better understand how complex geometries respond to applied loads, which may be time consuming or impossible using traditional methods such as hand calculations. It also helps to minimize the risk of part failure in real world conditions by revealing performance issues that may otherwise be overlooked.

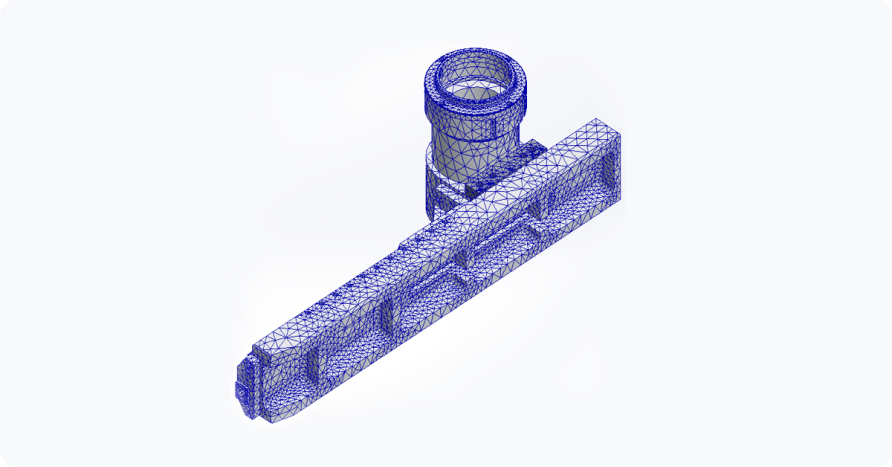

FEA simulations enable product designers to model complex assemblies and subject them to extensive testing virtually. This drastically reduces the number of physical prototypes that need to be made for testing purposes and cuts down on the number of design iterations required to arrive at a viable solution. Most importantly, the safety of the testing process can be enhanced since critically loaded components can be modelled and studied with a high level of accuracy prior to physical prototyping.

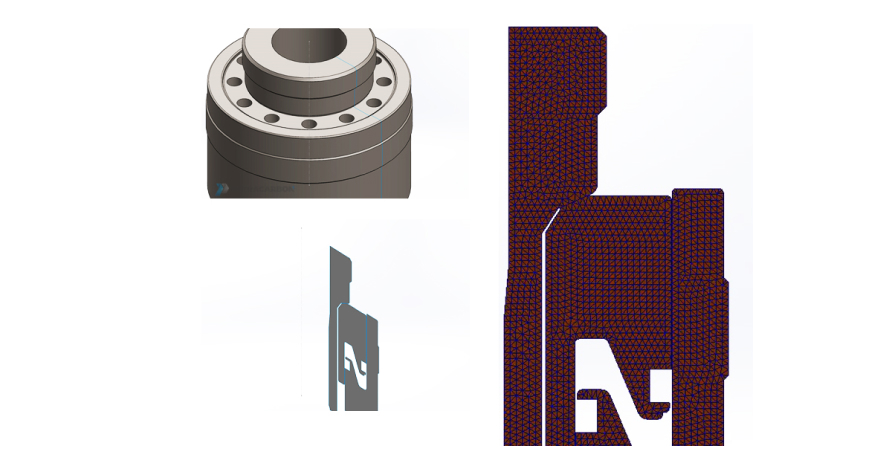

The ability to model complex parts enables designers to study their behavior in response to real world loading and identifying the weak links in a design. Often, an assembly can fail due to inadequate design of a single component. Therefore it is vital that the designer identifies critically loaded components and ensure they are adequately designed to increase the service life of a product as a whole.

With the ability to prototype products rapidly, accurately and safely, costs are reduced with a resulting decrease of lead time to commercialization. The ability to optimize a design also leads to a final product that is robustly designed, at the same time eliminating wastage arising from multiple iterations of physical prototyping and testing.