iNPIPE PRODUCTS™ specializes in pipeline pigging solutions, which are essential for maintaining the cleanliness and efficiency of pipeline systems. We are offering a range of products designed for various pipeline operations, including cleaning, inspection, and maintenance.

Essential tools for ensuring the integrity and quality of flange welds in pipeline systems.

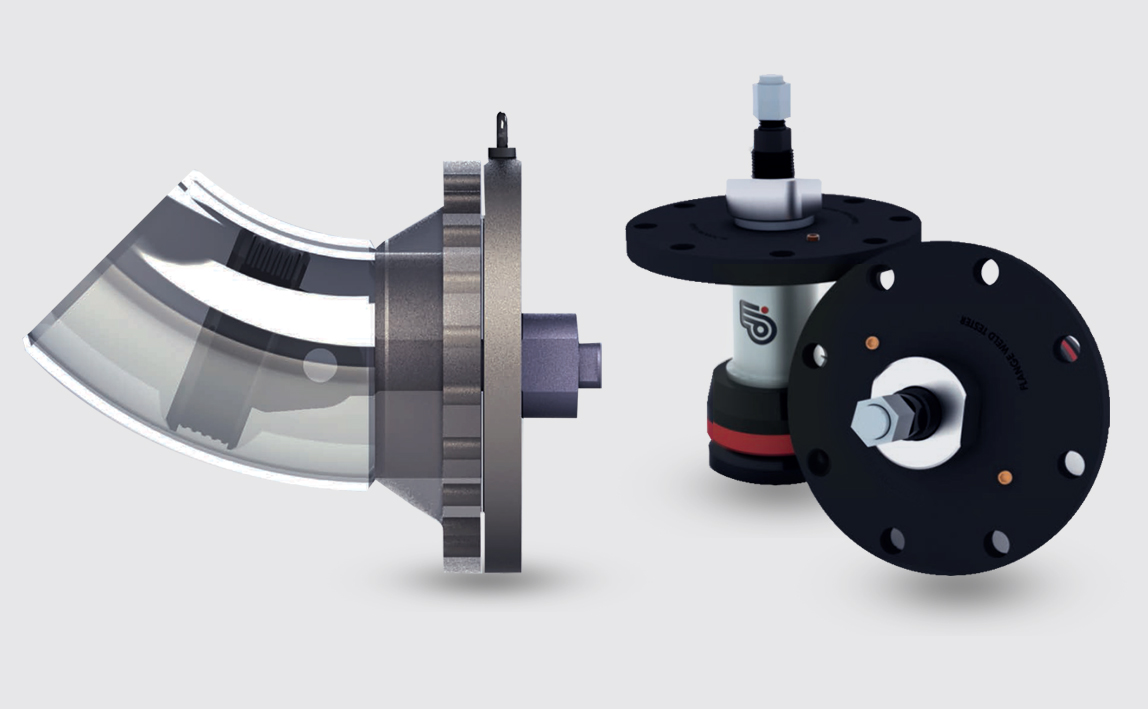

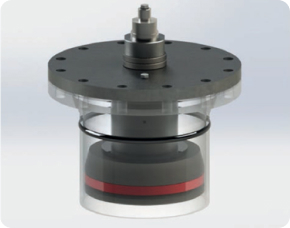

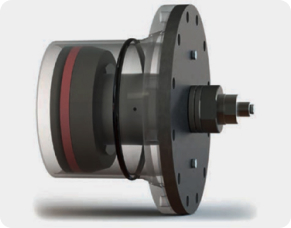

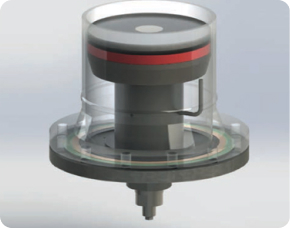

Internal Flange Weld Testers Purpose: Designed to inspect the quality of welds on the internal surfaces of flanges. They are used to detect defects such as cracks, incomplete fusion, or porosity that could compromise the strength and safety of the weld.

External Flange Weld Testers Purpose: Focuses on the external surfaces of flange welds. They are used to evaluate welds from the outside of the flange and identify defects that could affect the performance and safety of the pipeline.

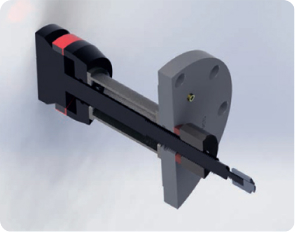

Orientation and location of the weld tester must be taken into consideration to ensure that all air is effectively bled from the cavity area. Venting chimneys are available to cover any test orientation required.

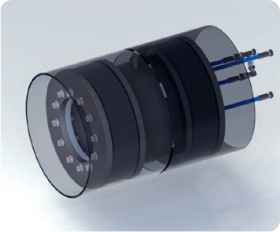

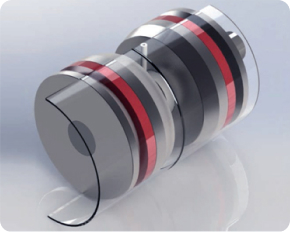

All weld testing equipment and plugs are available in mechanical and hydraulic options for tethered remote operation depending upon size, location, and actuation requirements. All products are supplied complete with full factory acceptance pressure test certificates which can be third-party witnessed (TPI) if required. Internal weld testers can be used in a number of options and orientations for testing butt welds to line pipe. Mechanical and hydraulic options provide for local or remote actuation through extended hoses.

Internal weld testers can also be used to test the effective sealing of flange-mounted ball valves. Depending upon application, testers can be purpose-manufactured to provide a specific length between the Posi-seals™. Flange weld testing can be achieved by either using the bespoke flange weld tester or by using an internal weld tester as illustrated. The weld is again located between the two Posi-seals and the weld is tested by pressure testing the cavity between the two energized seals.

For in-depth product specifications, download our flyer.

To find our more information, Visit www.inpipeproducts.com